A solemn ceremony of laying new power units was held today at the Turkmenbashi complex of oil refineries with the participation of President of Turkmenistan Gurbanguly Berdimuhamedov.

Speaking to the participants of the event, the head of state noted that in accordance with the program for socio-economic development of Turkmenistan for 2019-2025, the country's industrial enterprises, including the Turkmenbashi complex of oil refineries, have set great tasks. These include the construction of new technological facilities and ensuring their reliable operation.

"Based on this, we are launching the construction of two new gas turbine power plants with a design capacity of 70 Megawatts/hour at the Turkmenbashi complex of oil refineries and the reconstruction of the existing power plant," Berdimuhamedov said.

The Turkmen leader said that the construction of these facilities will be carried out by the Turkish company “Çalik Enerji”.

"They will be equipped with the most modern equipment produced by leading enterprises in European countries, and in 18 months they will be put into operation in full readiness. In General, all this is designed to ensure uninterrupted and reliable supply of electricity to new facilities, the commissioning of which is provided for by the above – mentioned program," the President of Turkmenistan stressed.

One of these facilities is a delayed coking and tar de asphalting plant, which is currently being built at the plant complex. Putting it into operation, along with increasing the depth of oil refining, will increase the output of liquefied gas, gasoline, diesel fuel and petroleum coke, as well as create additional jobs.

When implementing such important projects, the head of state said, special importance is attached to compliance with environmental requirements and innovative technologies. This is confirmed by the relevant certificates of reputable international organizations that have been awarded to large industrial, oil and gas and chemical production facilities built jointly with foreign partners.

Today's event has a special significance. During the years of independence, President Gurbanguly Berdimuhamedov stressed that our country, having become a state that builds and creates, implements major projects, has entered a number of dynamically and comprehensively developing countries of the world.

"Major projects that are currently being implemented in Turkmenistan, despite the ongoing difficult situation in the world, modern facilities and buildings being built and put into operation – all this is aimed at accelerating the development of the national economy, ensuring a prosperous and abundant life of the people," the Turkmen leader summed up his speech.

During the ceremony, a video was presented to the audience – a brief presentation of the production capabilities of the Turkmenbashi complex of oil refineries, which is one of the largest industrial enterprises in Central Asia and the Caspian region.

After gaining independence, the oil and gas industry of Turkmenistan faced an important task-to meet the needs of the national economy in the main types of petroleum products, to establish their export.

Taking these requirements into account, a program of reconstruction and technical re-equipment of the Turkmenbashi oil refinery was developed, which allowed to significantly increase production efficiency, create a flexible and reliable system for processing hydrocarbon raw materials, and produce products that are competitive on world markets.

As part of this large-scale program, catalytic reforming units with continuous catalyst regeneration (CCR) and millisecond catalytic cracking (MSCC), and a lube oil plant were built at TCOR. As a result, Turkmenistan was the first of the CIS countries to completely stop producing leaded gasoline, and significantly increased the production of high-octane brands of automobile fuel.

The first step in the development of the domestic oil and gas chemistry was the construction of a polypropylene complex (PPL) at the TCOR, which is based on liquefied gas coming from the millisecond catalytic cracking (MSCC) plant.

Today, granular propylene occupies one of the leading places in the list of products exported by Primorye petrochemicals. It is purchased by Russia, Japan, Turkey, Iran, Uzbekistan, Azerbaijan and other countries.

A significant part of the export product is sent to consumers by sea. For this purpose, a specialized terminal for storage and shipment of polypropylene has been built in the International seaport of Turkmenbashi.

In turn, the commissioning of the plant for the production of hydro treated diesel fuel (DHT) with a minimum content of sulfur and nitrogen at the country's leading petrochemical enterprise made it possible to fully meet the needs for diesel fuel that meets world environmental requirements, domestic automobile and tractor equipment, river vessels, and expand the export opportunities of the TCOR.

The world's leading developers of technologies that provide high – quality products, large companies and banks in Japan, Germany, France, the Republic of Korea, the USA, Turkey, Iran, Israel - "Chiyoda", "Itochu", "Nissho Ivai", "JGC", "Technip", "Hyundai Engineering", "Edeliyanu", "UOP", "Basell", "Merhav", "Nichimen", "Marubeni", "Eximbank", "JBIC", "Deutsche Bank" and others.

A 126.4 megawatt power plant with three gas turbines from the world-famous American company General Electric was built on the first-born of the domestic petrochemical industry. Powerful transformers and electric power equipment were supplied from Germany, France, Italy and other countries of the world.

At the same time, the primary oil refining units (ELOU-at) were upgraded, internal and external engineering communications were updated, new storage tanks for raw materials and finished products were built, an aviation kerosene purification unit, and a road and railway terminal for the shipment of liquefied gas.

It should be noted that the new installations being built at TCOR complement each other due to the widespread use of waste-free technologies in deep oil refining, the latest achievements in world practice. An example of this is a major investment project implemented by a consortium of LG International Corp. and Hyundai Engineering Co., Ltd (Republic of Korea).

Within its framework, plants designed for the production of high-octane grades of automobile gasoline that meet international quality standards have been built. The necessary components are extracted during vacuum distillation of fuel oil and processing of liquefied gas.

Two years ago at the Turkmenbashi oil refinery was installed with technological line for the production of biaxially oriented polypropylene films (BOPP). Among a variety of synthetic and natural packaging materials, worr films today occupy a leading position, pushing aside competitors such as cellophane, foil, polyamide or polyethylenefluorate.

Today, commercial products of the Turkmenbashi oil refinery, there are diverse types and brands of oil products. Among them are high-octane automobile gasolines of the a-80, a-92, A-95 brands, aviation, technical and lighting kerosene, diesel fuels, a wide range of technical lubricants, liquefied gas, petroleum coke, road and construction bitumen, granulated polypropylene and other goods sold through the state commodity exchange of Turkmenistan.

Currently, work is underway on the construction of a new delayed coking unit and tar de asphalting. The main objective of the project, implemented by a consortium of companies "WTL FZE" (OAE) and "Westport Trading Europe Limited" (USA) – processing of heavy residues of tar and fuel oil based on the technology of the company "Foster Wheeler". The capacity of the complex is 900 thousand tons of products per year.

In addition to total petroleum coke, the plant will produce liquefied gas and components for the production of gasoline. Light coke gas oil is also a raw material for the diesel fuel Hydro treating plant, which will produce Euro-5 automotive fuel. And heavy coke gas oil will be the raw material for the catalytic cracking unit operating at the plant.

Located near the city of Turkmenbashi, the Kenar oil products storage and shipment facility is connected to the Turkmenbashi complex of oil refineries by a network of pipelines that carry oil products to the offshore oil loading terminal.

From here, ships of the national Navy and other States export them. An automated railway overpass has also been built here, which makes it possible to load 3 million 850 thousand tons of petroleum products per year, including 1 million 800 thousand tons of automobile gasoline, into tanks and send them by rail.

The most important aspect of technical re-equipment of the first-born of the domestic oil refining industry is the preservation of environmental well-being in the coastal zone of the Caspian Sea, taking into account the national tourist zone "Avaza" and the Hazar state reserve located here.

An extensive program of environmental protection measures includes conducting research to assess the state and develop measures to clean up sea bays, restore their natural and biological resources, and dispose of oil slags and oil-containing soils. Modern treatment facilities have been built at the TCOR, and regular monitoring of air, water, and soil cleanliness has been established.

On behalf of the President of Turkmenistan Gurbanguly Berdimuhamedov, a tender is being held for the development of a feasibility study for the "Conceptual strategy for the development of the Turkmenbashi complex of oil refineries and the Seydi oil refinery".

We will analyze in detail the capabilities of TCOR and SOR, identify promising areas for their further development, as well as the optimal range of petroleum products, taking into account modern requirements and demand on world markets.

In particular, it is planned to build new technological facilities at the Turkmenbashi oil refinery, which will allow increasing the depth of oil refining to above 90 percent. These include a complex of Hydro treating units for diesel fractions and gasoline, catalytic cracking and coking with a hydrogen production unit; a unit for catalytic cracking of heavy residues of refined oil products, as well as a unit for the production of high-quality base technical oils.

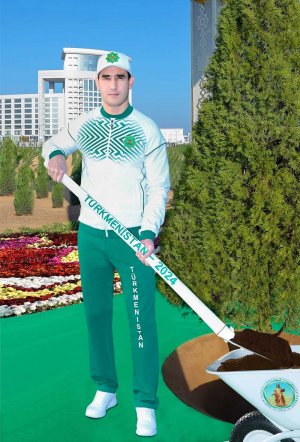

At the end of the video the head of state to the applause of the audience was put in the Foundation of a special capsule with the message addressed to future generations of Turkmenistan and according to tradition, gave the symbolic start of the construction, throwing first shovels of concrete in the Foundation of buildings.

The oil and gas industry is the leading sector of the economy of Turkmenistan, which has large reserves of hydrocarbon raw materials. In accordance with the priorities of the state policy, significant investments are allocated for the modernization and diversification of the fuel and energy complex. Investment projects implemented in our country in cooperation with foreign partners, including in the field of petro chemistry, are focused not only on domestic interests, but also contribute to the development of fruitful cooperation that meets the goals of common well-being, the state news Agency of Turkmenistan reports.